The Role of Compliance and Maintenance

The Role of Compliance and Maintenance

Despite its advantages, the LNG industry also faces several challenges. The initial investment for liquefaction plants and infrastructure is substantial. Additionally, fluctuating natural gas prices can deter investment and create uncertainty in the market. Environmental concerns regarding the fracking process used to extract natural gas can lead to public opposition and regulatory hurdles.

In conclusion, gas coalescers play a vital role in the oil and gas industry by effectively separating liquid droplets from gas streams. By removing impurities and contaminants from the gas stream, gas coalescers help to ensure the smooth operation of various processes and prevent equipment damage and loss of valuable product. With the right design and configuration, gas coalescers can significantly improve the efficiency and reliability of oil and gas production facilities.

Furthermore, the odorization of natural gas—a critical safety measure—ensures that any leaks can be detected easily, as natural gas is odorless and tasteless in its pure form. The addition of a distinct odor, typically that of rotten eggs, allows for immediate detection of leaks, thereby protecting public health and safety.

Pneumatic control valves come in various types, each designed for specific applications. Ball valves, butterfly valves, and solenoid valves are prevalent in pneumatic systems. Ball valves provide quick shut-off capabilities, while butterfly valves offer a more compact and lightweight solution for regulating flow. Solenoid valves, on the other hand, use electromagnetic coils to control flow, allowing for precise on-off switching in applications where automated control is required.

How Does a Pressure Reducing Valve Work?

Safety Features and Technological Advancements

Conclusion

Conclusion

4. Versatility Air control valves are versatile components that can be tailored to fit a wide range of applications. Whether in automotive assembly lines, food processing plants, or packaging industries, these valves can be adapted to meet specific needs.

Importance of Gas Regulators

Blood pressure, a vital sign that reflects the force of blood against the walls of our arteries, plays a crucial role in our overall health. Maintaining optimal blood pressure levels is essential for preventing various health issues such as heart disease, stroke, and kidney problems. As medical technology continues to advance, blood pressure control devices have emerged as valuable tools in the management and monitoring of hypertension.

Operational Principles

2. Efficiency By maintaining consistent pressure levels, these devices enhance the efficiency of gas appliances. Appliances designed for specific pressure levels operate more effectively, leading to reduced energy waste and operational costs.

- Process Control With the ability to adjust flow dynamically, regulating valves contribute to the overall control of processes, allowing for greater flexibility and responsiveness to changing conditions.

2. Manual Shut-off Valves These valves require manual intervention to close off the gas supply. They are often installed in strategic locations for emergency shut-off.

In addition to safety, appliance regulators contribute to the overall efficiency of household devices. By ensuring that appliances operate under optimal conditions, they help reduce energy consumption and minimize waste. For example, temperature and pressure regulators in HVAC systems can optimize energy use, leading to lower utility bills and a smaller carbon footprint. This not only benefits the consumer financially but also contributes to broader environmental sustainability efforts.

2. Metering Equipment Metering stations measure the quantity of gas being distributed, which is essential for billing and monitoring consumption.

One of the main advantages of employing natural gas filter separators is the protection they provide for downstream equipment. By removing contaminants, filter separators help extend the lifespan of compressors, turbines, and other essential machinery, leading to decreased maintenance costs and increased operational efficiency.

As global demand for efficient and sustainable energy solutions grows, the role of gas boosters in gas transport systems cannot be understated. These devices enhance pressure, allowing for more effective and safer transportation of various gases across industries. Their adaptability and efficiency make them invaluable in today's energy landscape, supporting a transition towards a more sustainable future. As technology continues to evolve, gas boosters are likely to play an even more pivotal role in enhancing energy infrastructure worldwide.

3. Excess Flow Valves These valves detect and respond to sudden surges in gas flow, which may indicate a rupture in the line. They automatically close to prevent further gas from escaping into the environment.

1. Open/Close Control Simple on/off operation based on threshold settings.

Conclusion

2. Safety Valves Safety is paramount in any industrial operation. Safety valves are critical components that protect the system from pressure surges and potential hazards. They are designed to release excess pressure automatically, preventing damage to equipment or injury to personnel.

Additionally, electric valves typically require less maintenance than their pneumatic counterparts, leading to reduced labor costs and downtime. Their design can accommodate a range of operating environments, including varying temperatures and pressures, making them versatile for different applications.

3. Safety Features Gas pressure vessels are equipped with safety devices, such as pressure relief valves, that prevent over-pressurization. These devices are essential to ensure the safety of the vessel's operation and to protect personnel and nearby facilities.

Gas pressure reducers have a wide range of applications across different sectors. In the medical field, for instance, oxygen pressure regulators are crucial for supplying patients with the correct amount of oxygen at a safe pressure. Similarly, in the welding industry, gas regulators are used to control the pressure of welding gases, ensuring optimal performance and safety during operations.

5. Hypertension Canada

Molecular Weight: 412.207

Reliable Supply We have a large warehouse facility and a team of experienced logistics professionals who ensure that our customers receive their orders promptly and efficiently Reliable Supply We have a large warehouse facility and a team of experienced logistics professionals who ensure that our customers receive their orders promptly and efficiently

Reliable Supply We have a large warehouse facility and a team of experienced logistics professionals who ensure that our customers receive their orders promptly and efficiently Reliable Supply We have a large warehouse facility and a team of experienced logistics professionals who ensure that our customers receive their orders promptly and efficiently lithopone b311 powder quotes supplier. We also maintain a large inventory of lithopone B311 powder to meet the varying demands of our customers.

lithopone b311 powder quotes supplier. We also maintain a large inventory of lithopone B311 powder to meet the varying demands of our customers.

5. Regulatory compliance The MSDS should also include information on regulatory requirements for the safe handling and use of lithopone, including any permits or certifications that may be necessary.

When E171 is part of a food product, it passes through the digestive system without causing harm because E171 combines with the other ingredients.

In its statement to USA TODAY, the FDA maintained that, in all post-approvals for food additives, our scientists continue to review relevant new information to determine whether there are safety questions and whether the use of such substance is no longer safe under the Federal Food, Drug, and Cosmetic Act.

After oral ingestion, the absorption of titanium dioxide particles is low, however they can accumulate in the body, Maged Younes, chair of the European Food Safety Authority's expert Panel on Food Additives and Flavourings, said in a May 2021 statement.

Overall, buff percentage is a critical factor that manufacturers of titanium dioxide must carefully manage to ensure the quality, consistency, and cost-effectiveness of their products. By investing in advanced technology and processes to control buff percentage, manufacturers can meet the specific requirements of their customers and maintain a competitive edge in the market. As the demand for titanium dioxide continues to grow across various industries, manufacturers must continue to innovate and improve their processes to meet the evolving needs of their customers.

In a lawsuit filed last week, a consumer alleged that Skittles were unfit for human consumption because the rainbow candy contained a known toxin – an artificial color additive called titanium dioxide.

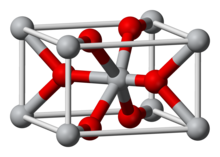

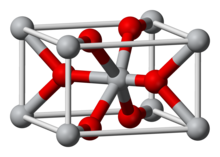

Magnesium can be made by several methods (Fig. 1), but the most common method of manufacture is by the electrolytic process, as for example the electrolysis of magnesium chloride.

Titanium dioxide comes in the form of a white powder and is sometimes used in cosmetics to adjust a color to a lighter shade. This is also why it can produce a white cast.

ROS were detected through the colorimetric assay employing the nitro-blue tetrazolium salt (NBT salt) by reading the absorbance of the reduced blue molecule.

Overall, the Food Directorate's comprehensive review of the available science of TiO2 as a food additive showed:

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.

talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.Water solubles, %

The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare

The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare 77891 titanium dioxide factory. It actively seeks to reduce its carbon footprint and engages in initiatives that foster biodiversity and support local ecosystems.

77891 titanium dioxide factory. It actively seeks to reduce its carbon footprint and engages in initiatives that foster biodiversity and support local ecosystems.In conclusion, the demand for dyes and pigments is on the rise, and having a reliable titanium dioxide factory like CAS 13463-67-7 is essential for meeting this demand. With its dedication to quality, sustainability, and innovation, CAS 13463-67-7 is well-positioned to continue serving the needs of its customers and the industry as a whole.